Are you interested in creating a complex configurable product for your online webshop? StudioFG can help you with this using technologies like grasshopper /rhino in combination with shapediver and the API of your e-commerce system. Shopify + shapediver With a market share of about 30% Shopify has proven itself to be a robust e-commerce system. Together with the shapediver plugin your webshop can be rtransformed into a fully configurable product experience with downloadable models and with easy checkout. You can engage customers with customizable products and process complex orders right away. Similar functionalities can be achieved for WooCommerce or other…Continue readingParametric models for product configurators

Grasshopper / Rhino3D

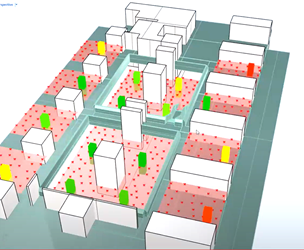

The ability to analyze performance is an important quality of parametric design. Especially during discussions with curators, it became clear how much potential there is in the ability to analyze object data and design data in a parametric setup while using a central database. Several areas of analysis emerged. One can think of: Security: are objects visible by security cameras Insurance: are objects in safe places Logistics: do objects fit, e.g., do the works fit through the entrance But one can also analyze the building itself: What are the most visible places? Which places get the most daylight? Which places…Continue readingProof of Concept #4 | Analyze Visibility

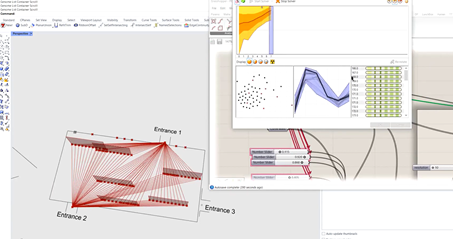

In this proof of concept, we’ll explore an example where we let the computer do the work for us. A parametric algorithm in grasshopper can work as a design tool where the user interacts with sliders and data. But in this example, we will explore a proof of concept where we let the computer present different outcomes. The computer will iterate over many options to present a set of good results to the user. The decision framework is basically designed by the designer, because he/she can dictate to the computer which solutions are preferable. This method can be used in…Continue readingProof of Concept #3 | Maximize visibility with an evolutionary solver

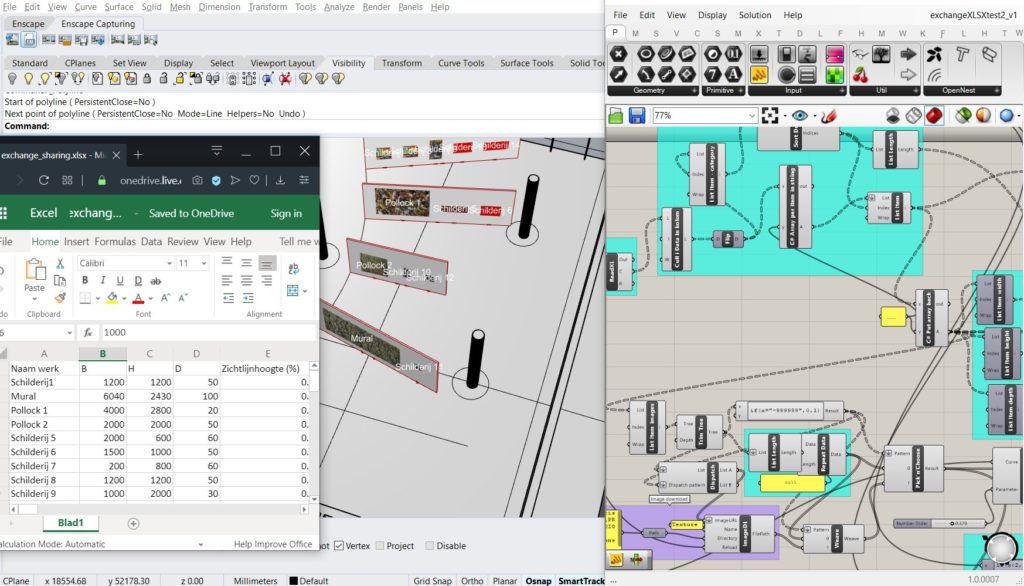

This is an initial Proof of Concept for Gallerbee worked out using an exchange between an online Excel document that interacted with a 3D design via Grasshopper, Excel was chosen because it is easy to use for initial testing and is a frequently chosen program by exhibition organizations. The following data can be processed in the Excel table: Delete or add artworks. Name/rename artworks. Change/add dimensions. Add information such as year of creation, artist’s name, preferred position from the floor. Link to an image file of the artwork. And especially important for this test: categorize the works Naturally, there are…Continue readingProof of Concept #1 | Parametric Exhibition from Excel

Grasshopper3D can also be used for graphic design, i.e. parametric graphic design for 2-dimensional applications. This post is about building an image tracer based on brightness and contrast.Continue readingImage tracer with pattern options

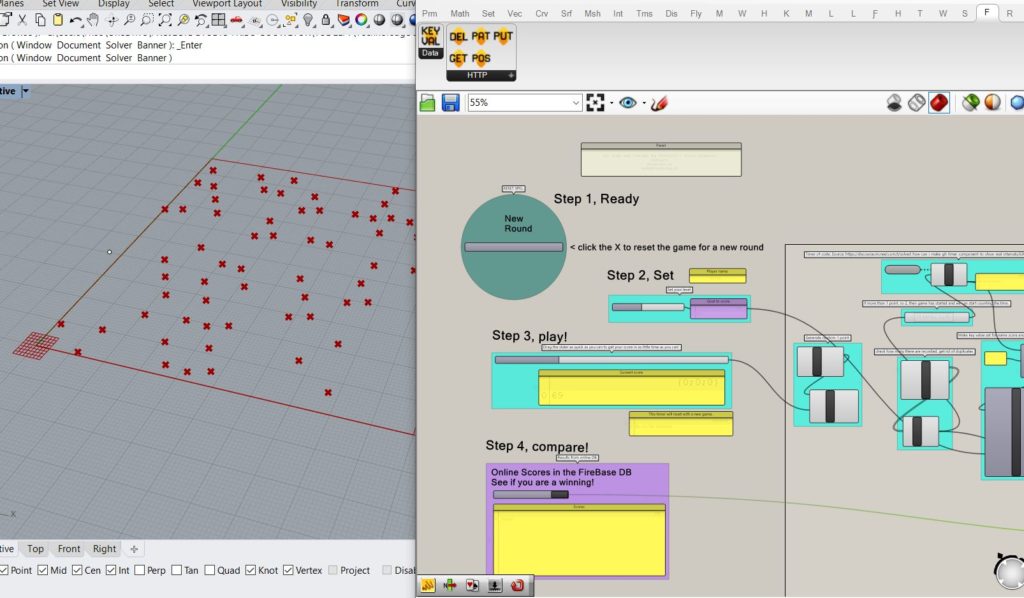

When teaching Grasshopper, it is sometimes nice to take a slightly different approach. For example in the form of a game. DragRace is about uploading scores to an online database and trying to win with the fastest score!Continue readingGrasshopper game: DragRace with Firebase

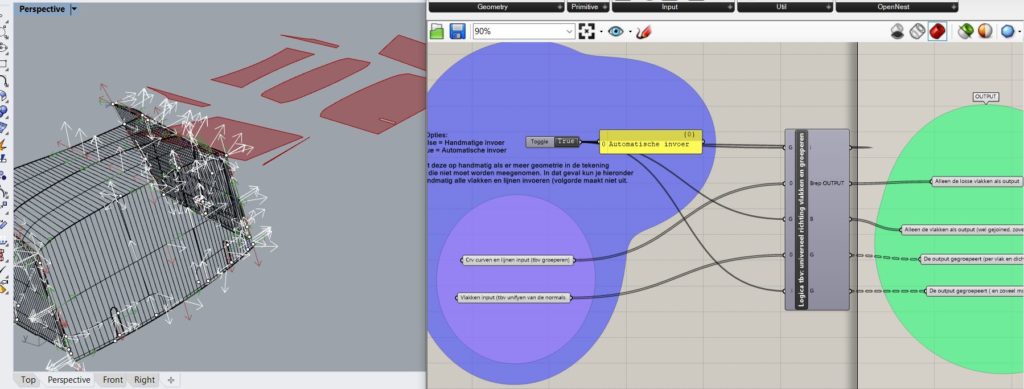

For a sail making company, StudioFG has developed several scripts to automatically generate drawings for hems and other fabric parts. Read here about this project.Continue readingAutomatic generation of cut-lines for a boat cover

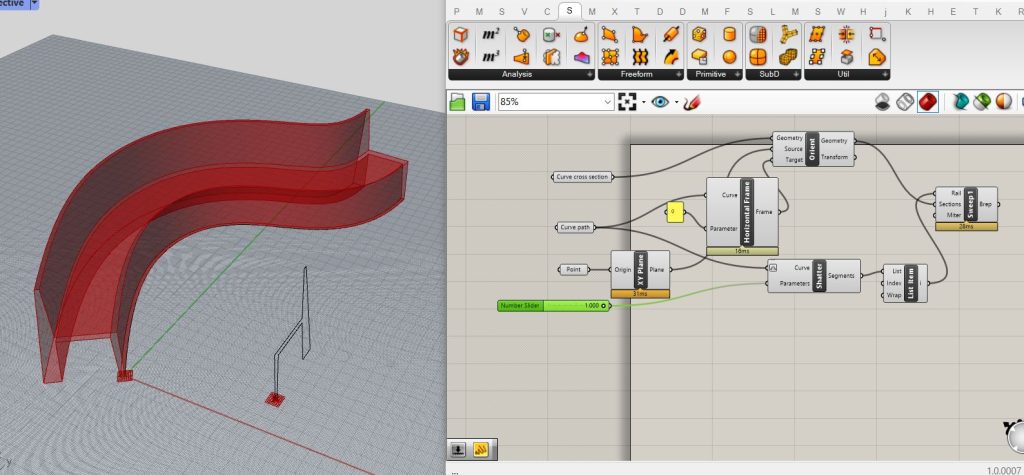

With great pleasure we again teach the course Technoledge in which we realize a pavilion together with master students of TU Delft and PWR Wroclaw from design to realization in 7 weeks. The basis for the production is the parametrically controllable flexmould.Continue readingComputational design pavilion with the TU Delft